950 GC

The new Cat® 950 GC Wheel Loader is designed specifically to handle all the jobs on your worksite from material handling and truck loading, to general construction, to stockpiling. This machine is purpose-built to be just the right machine to get your everyday jobs done. Great machine performance combined with low owning and operating costs make the 950 GC the right choice for your business.

Net Power - ISO 9249

202 HP

Engine Model

Cat C7.1

Bore

4.1 in

Specification

Value

Net Power - ISO 9249

202 HP

Engine Model

Cat C7.1

Bore

4.1 in

Stroke

5.3 in

Displacement

427.8 in³

Maximum Gross Torque - 1,400 rpm

752 ft-lb

Rated Net Power - 2,200 rpm - ISO 9249

202 HP

Rated Gross Power - 2,200 rpm - ISO 14396

225 HP

Maximum Gross Power - 2,000 rpm - ISO 14396

229 HP

Maximum Net Torque - 1,300 rpm

687 ft-lb

Specification

Value

Operating Weight

41174 lb

Specification

Value

Bucket Capacities

2.5-4.4 m³ (3.3-5.75 yd³)

Specification

Value

Breakout Force

33047 lb

Note (1)

**Compliance to ISO (2007) 14397-1 Sections 1 thru 5.

Static Tipping Load - Full 40° Turn - Rigid Tires**

24685 lb

Static Tipping Load - Full 40° Turn - ISO 14397-1*

23155 lb

Note (2)

*Full compliance to ISO (2007) 14397-1 Sections 1 thru 6, which requires 2% verification between calculations and testing.

Specification

Value

Forward - 1

4.4 mile/h

Forward - 2

7.8 mile/h

Forward - 3

13.7 mile/h

Forward - 4

21.1 mile/h

Reverse - 1

4.4 mile/h

Reverse - 2

7.8 mile/h

Reverse - 3

13.7 mile/h

Specification

Value

Steering System - Pump Type

Piston

Hydraulic Cycle Time - Dump, at Maximum Raise

1.2 s

Hydraulic Cycle Time - Total Cycle Time

10.1 s

Hydraulic Cycle Time - Lower, Empty, Float Down

2.8 s

Hydraulic Cycle Time - Raise from Carry Position

6.1 s

Implement System - Optional 3rd Function Maximum Flow

74 gal/min

Implement System - Maximum Pump Output at 2,200 rpm

65.5 gal/min

Implement System Pump Type

Piston

Implement System - Maximum Operating Pressure @ 50 ± 1.5 L/min (13.2 + 0.4 gal/min)

4047 psi

Implement System - Optional 3rd Function Maximum Pressure @ 70 L/min

2999 psi

Specification

Value

Brakes

Brakes meet ISO 3450

Specification

Value

Choices

Choices include: 23.5-25 16PR, L3 (Triangle); 23.5R25, L3 (Triangle); 23.5R25, L3 (Bridgestone)

Specification

Value

ROPS/FOPS

ROPS/FOPS meet ISO 3471 and ISO 3449 Level II standards

Specification

Value

Differential - Final Drives - Front

10.6 gal (US)

Crankcase

5.3 gal (US)

Fuel Tank Size

76.6 gal (US)

Differential - Final Drives - Rear

10 gal (US)

Transmission

11.9 gal (US)

Hydraulic Tank

31.7 gal (US)

Cooling System

12.7 gal (US)

Specification

Value

B-Pin Height

13.7 ft

B-Pin Height - Carry

2.2 ft

Lift Arm Clearance

12 ft

Centerline of Rear Axle to Edge of Counterweight

6.6 ft

Height - Top of ROPS

11.4 ft

Height - Top of Exhaust Pipe

11.8 ft

Height - Top of Hood

8.4 ft

Ground Clearance

1.5 ft

Wheel Base

10.8 ft

Centerline of Rear Axle to Hitch

5.4 ft

Rack Back - Maximum Lift

60 °

Dump Angle at Maximum Lift

52 °

Rack Back - Carry

45 °

Rack Back - Ground

40 °

Height - Center Line of Axle

2.5 ft

Specification

Value

Turning Radius - Inside of Tires

11.2 ft

Turning Radius - Outside Edge of Counterweight

20.3 ft

Turning Radius - Outside of Tires

20.2 ft

Width - Over Tires

9 ft

- Cat® C7.1 engine offers high power density with a combination of proven electronic, fuel, and air systems.

- Engine emissions are equivalent to U.S. EPA Tier 3.

- Thorough component choice, design, and in-machine validation processes result in excellent reliability and uptime.

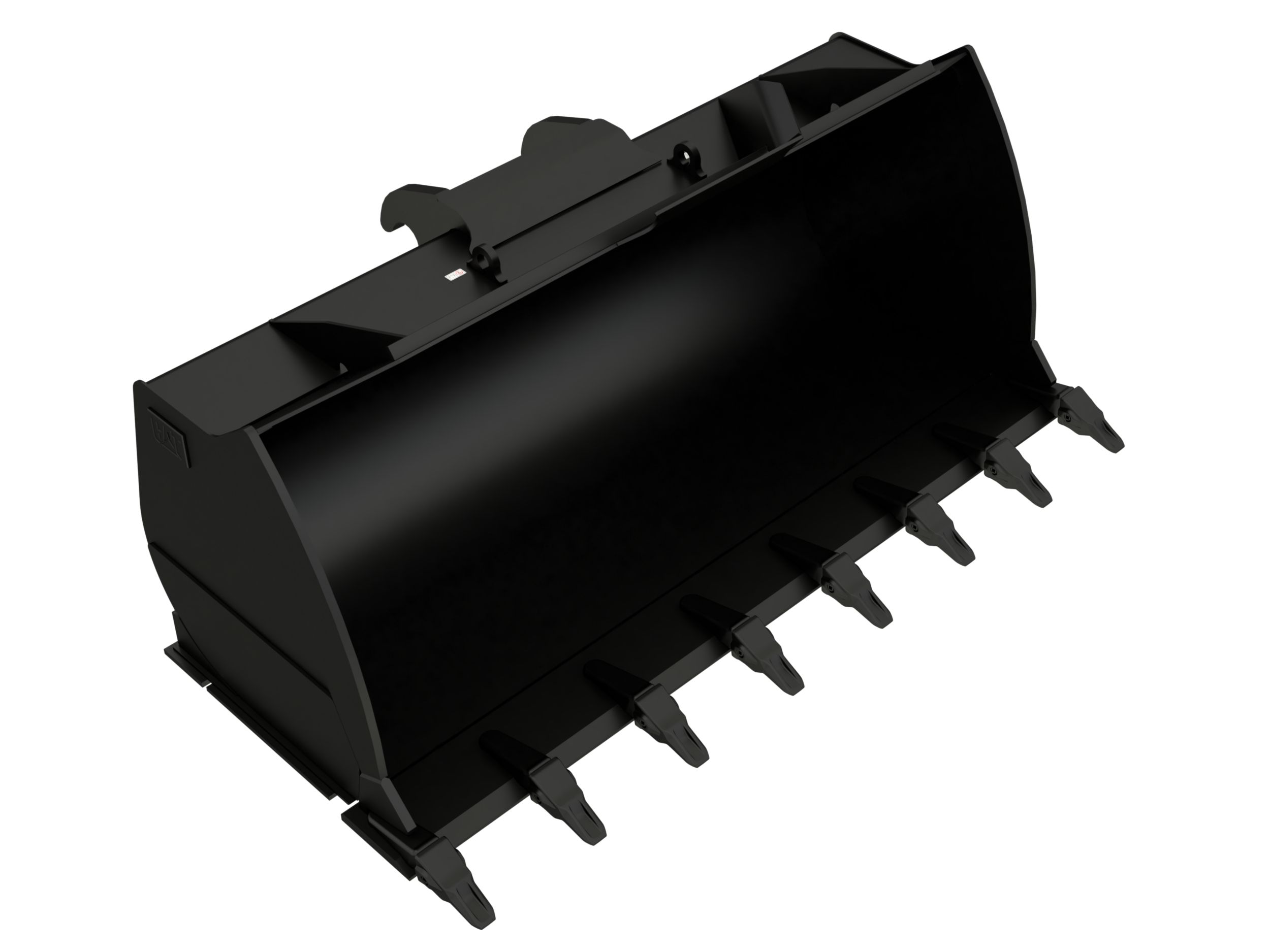

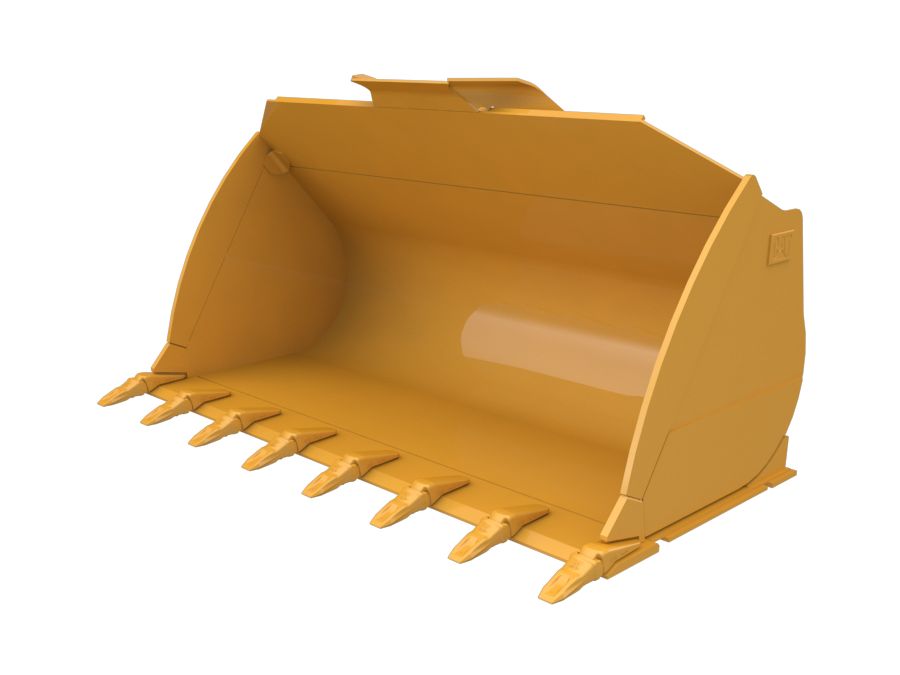

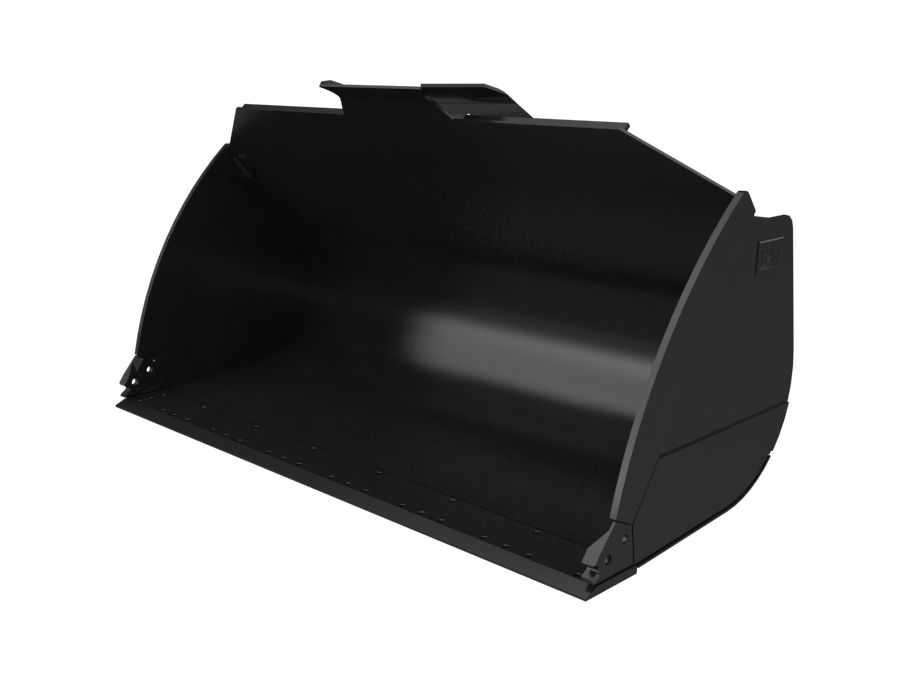

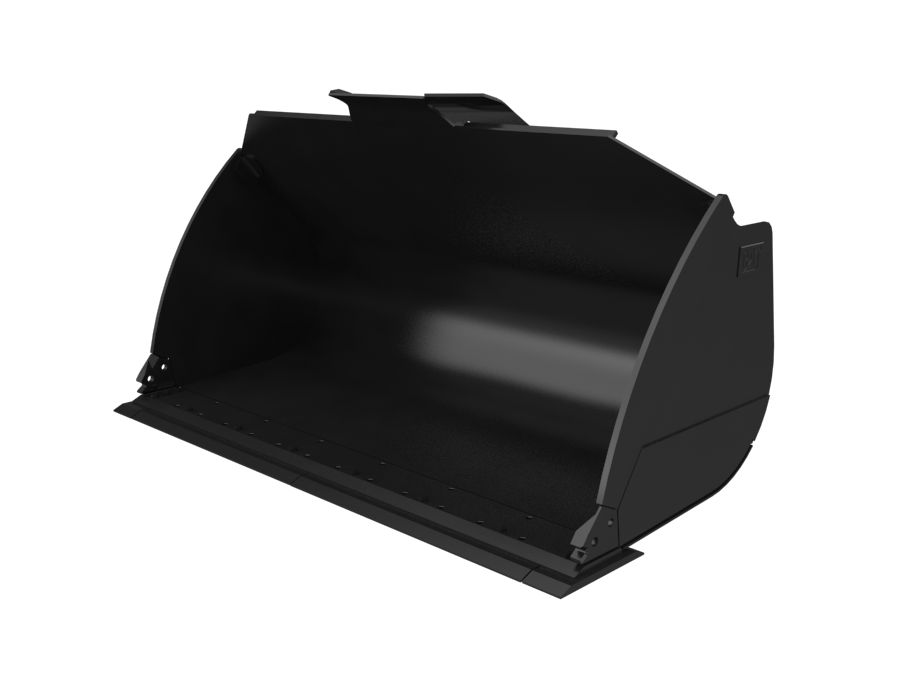

- The proven Cat Z-bar linkage geometry with Performance Series Buckets offer excellent penetration into the pile and high breakout forces. Combined with best-in-class standard dump clearance, this results in low fuel consumption and exceptional production capabilities.

- Cat designed, electronically controlled, automatic powershift transmission features shift protection and is equipped with a split flow oil system for efficiency, durability, and smoother gear changes.

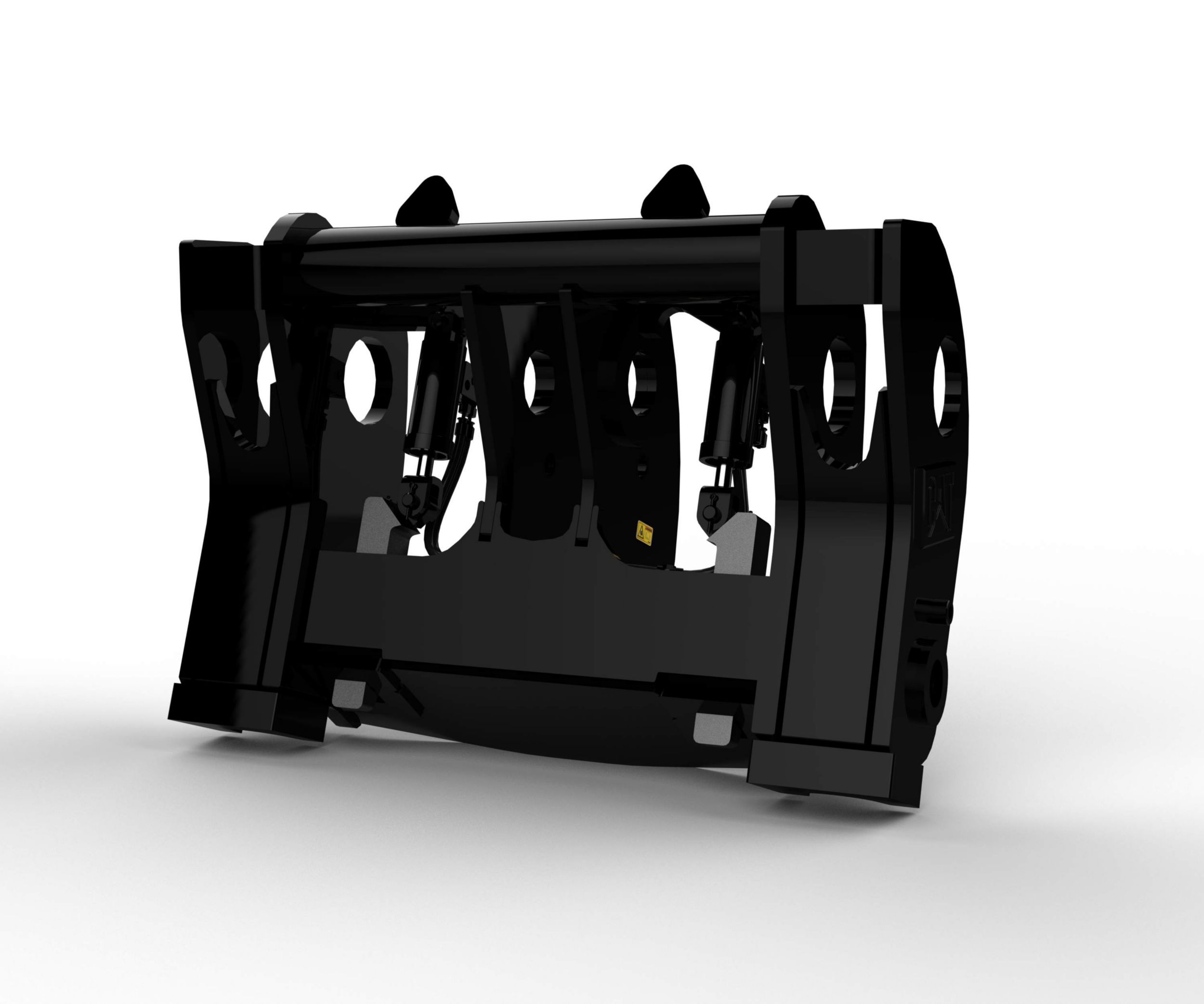

- Optional Fusion™ quick-coupler control features a selectable kickout to adjust for efficient bucket and fork applications.

- Engine Idle Management System (EIMS) and Auto Engine Idle Shutdown (EIS) maximize fuel efficiency by reducing engine rpm after a specified amount of idle time.

- Electronically controlled, hydraulically driven variable speed fan adjusts to meet the varying cooling requirements of the machine. This results in a reduced average fan speed, lowering fuel consumption, noise levels, and radiator plugging.

- Load sensing hydraulics produce flow and pressure for the implement system upon demand and only in amounts necessary to perform the needed work functions. This state-of-the-art system results in low fuel consumption.

- The spacious cab features easy, intuitive controls and excellent visibility which provides a comfortable working environment for efficient all day operation.

- Pilot-operated hydraulic implement controls deliver comfortable, low-effort operation. Two single-axis levers or one joystick are available. Both arrangements are equipped with kick-down switches.

- The adjustable steering column includes the F-N-R shifter and turn signal control lever.

- Unmatched viewing area with a wide, flat, and distortion-free front windshield.

- The glass stretches to the floor of the cab for excellent visibility to the bucket and front tires.

- The cab roof has channels which direct rain off the corners of the cab, keeping windows clear.

- Air conditioning system is standard. Ten louvered vents allow the operator to direct the air flow to remain productive and efficient all shift long.

- Ladders are standard on both sides of the machine to easily access the platforms.

- Platforms are equipped with guard- and handrails for safe access to the cab.

- The main cab door opens to the front and provides wide access to the operator environment.

- Front and back wipers ensure that a clear view is maintained.

- External rearview mirrors with integrated spot mirrors are standard.

- A rear vision camera is standard to clearly monitor movement behind the machine.

- Hinged wheel guards, easy removal/re-install.

- Optional windshield and power train guards.

- Grouped service points and sight gauges allow for easy daily maintenance.

- Convenient access to left, right, and rear of engine compartment provides excellent serviceability.

- Electrical and hydraulic service centers, along with additional key serviceability features, help make servicing and in-field component exchange quick, easy, and efficient.

- A rear swing-up grill gives easy cleaning access to the cooling cores.

- Hinged wheel guards are easy to remove/re-install, providing wide access to all maintenance points and to the engine compartment.

- Optional power train bottom guard protects the machine against damage to reduce downtime.

- Optional integrated Cat Autolube system provides full lube system monitoring and diagnostic test visibility. One-button control, including fault flash function.

- Caterpillar design and manufacturing techniques assure outstanding service life.

- This optional kit is simple to install compared to other 3rd party payload systems*.

- On-the-go weighing** for precise load targets with proven accuracy, flexible installation, and easy calibration and setup.

- Brings payload weighing to the cab so operators can work more productively and deliver consistently accurate loads.

- Increases productivity, weighing while lifting with no interruptions in loading cycle.

- High efficiency: load to exact specification, load more trucks faster, and move more material for more revenue.

- Improve efficiency with less rework; save time, labor, fuel,and costs.

* Not available in all markets

** Not legal for trade

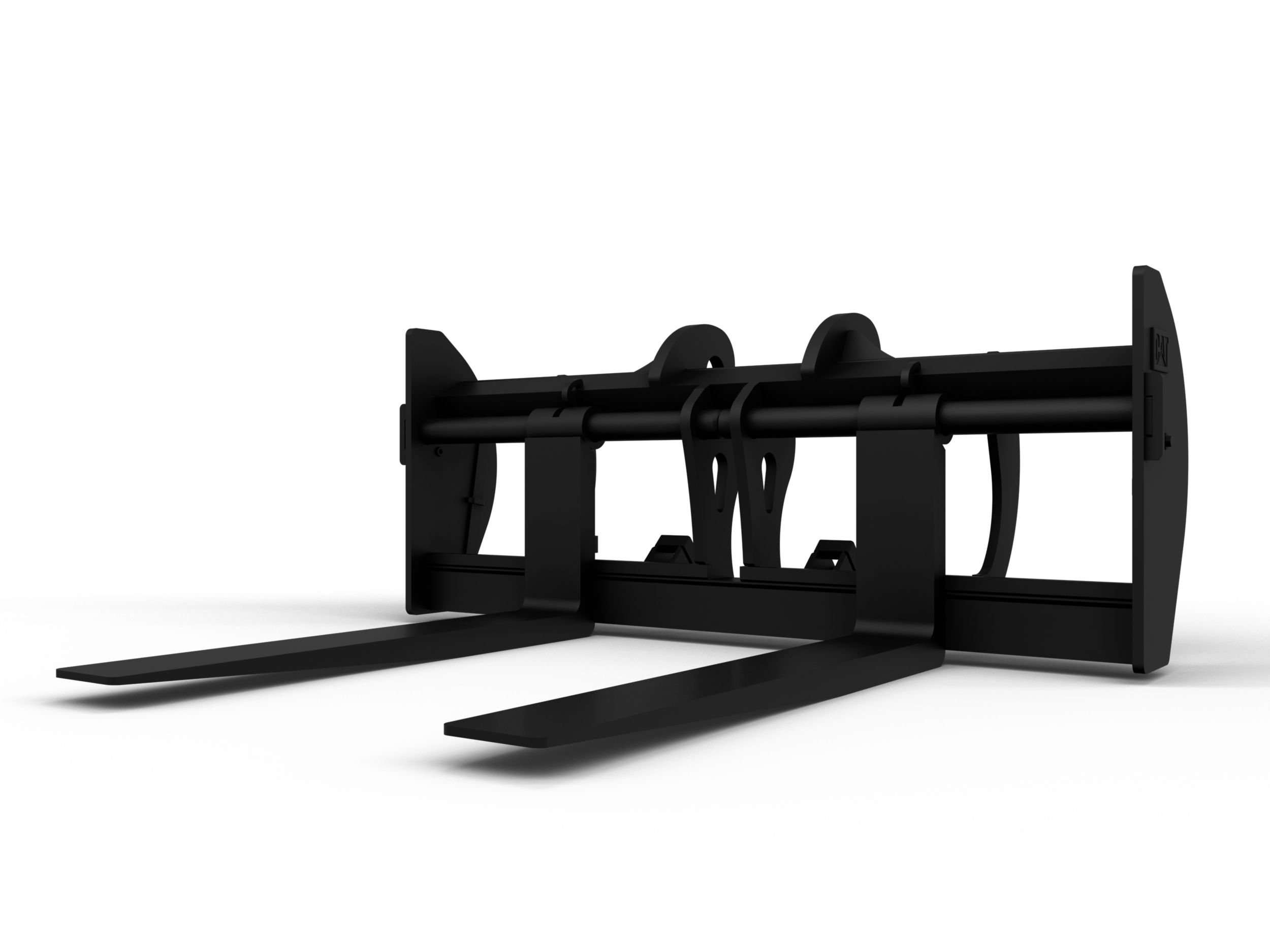

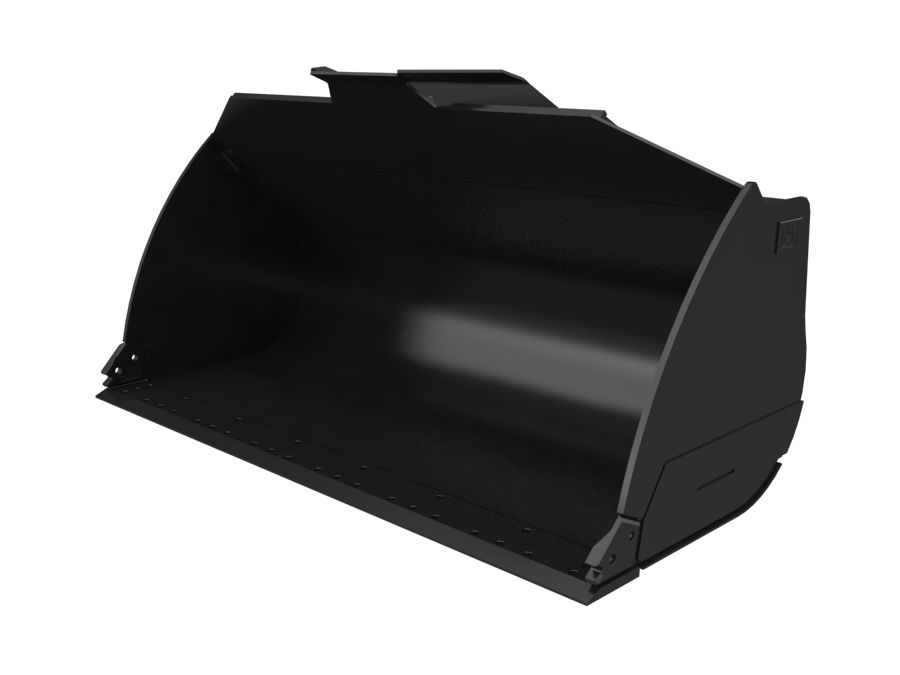

1524 mm (60 in) Fusion

1830 mm (72 in) Fusion

GC Flat Floor PS, 3.3m³ (4.25yd³), Pin On

GC Flat Floor PS, 3.1m³ (4yd³), Pin On

GC Flat Floor PS, 3.1m³ (4yd³), Pin On

Standard Flat Floor PS, 3.1m³ (4yd³), Pin On

Standard Flat Floor PS, 3.1m³ (4yd³), Pin On

Standard Flat Floor PS, 3.3m³ (4.25yd³), Fusion

Standard Flat Floor PS, 3.3m³ (4.25yd³), Fusion

GC Flat Floor PS, 3.3m³ (4.25yd³), Pin On

Standard Flat Floor PS, 3.3m³ (4.25yd³), Pin On

Standard Flat Floor PS, 3.3m³ (4.25yd³), Pin On

Standard Flat Floor PS, 3.6m³ (4.75yd³), Pin On

Standard Flat Floor PS, 3.6m³ (4.75yd³), Pin On

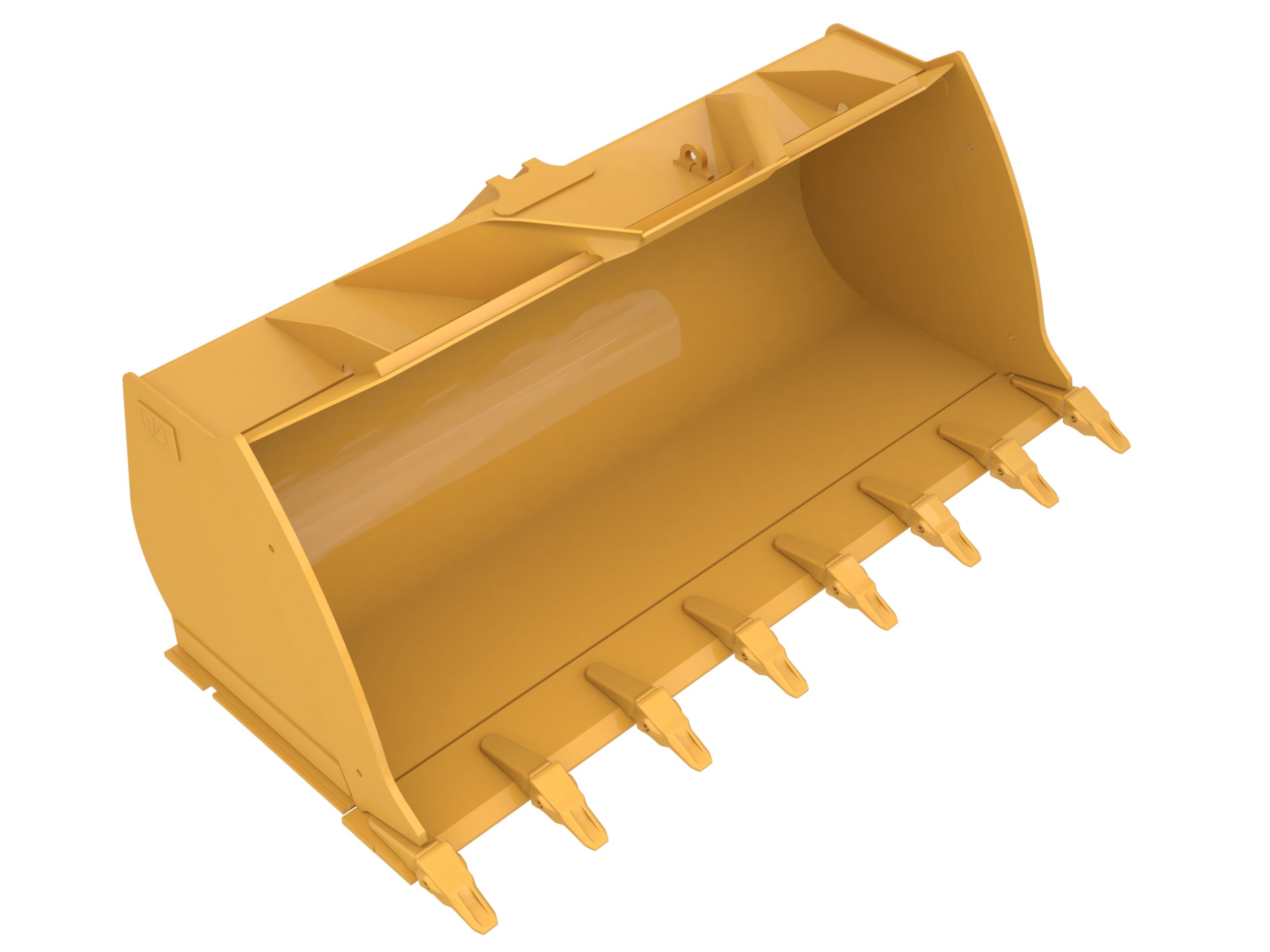

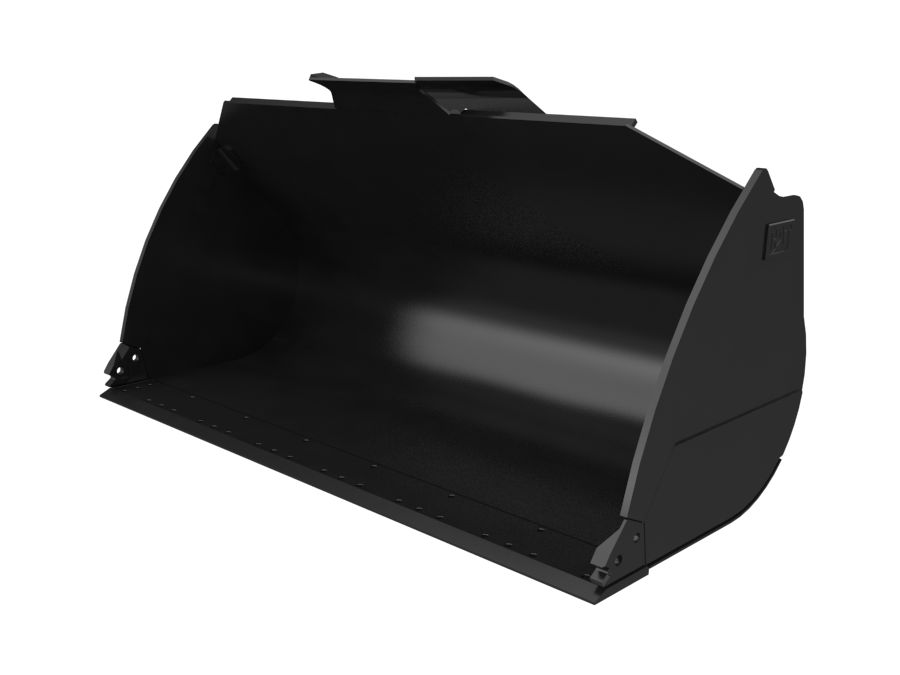

Flat Floor Bucket 3.3m³ (4.25yd³)

Flat Floor Bucket 3.6m³ (4.75yd³)

Flat Floor Bucket 3.3m³ (4.25yd³)Performance Series

Flat Floor Bucket 3.3m³ (4.25yd³)Performance Series

Flat Floor Bucket 3.4m³ (4.50yd³)Performance Series

Flat Floor Bucket 3.4m³ (4.50yd³)Performance Series

Flat Floor Bucket 3.8m³ (5.00yd³)Performance Series

Flat Floor Bucket 3.8m³ (5.00yd³)Performance Series

Flat Floor Bucket 3.8m³ (5.00yd³)Performance Series

Flat Floor Bucket 3.3m³ (4.25yd³)Performance Series

Flat Floor Bucket 3.4m³ (4.50yd³)Performance Series

Flat Floor Bucket 3.3m³ (4.25yd³)Performance Series

Flat Floor Bucket 3.6m³ (4.75yd³)Performance Series

Flat Floor Bucket 3.2m³ (4.25yd³)Performance Series

Flat Floor Bucket 3.4m³ (4.50yd³)Performance Series

Flat Floor Bucket 3.8m³ (5.00yd³)Performance Series

Flat Floor Bucket 3.4m³ (4.50yd³)Performance Series

Flat Floor Bucket 3.6m³ (4.75yd³)Performance Series

Flat Floor Bucket 3.1m³ (4.00yd³)Performance Series

Flat Floor Bucket 3.3m³ (4.25yd³)Performance Series

Flat Floor Bucket 3.3m³ (4.25yd³)

Flat Floor Bucket 3.3m³ (4.25yd³)

Flat Floor Bucket 3.8m³ (4.97yd³)

Flat Floor Bucket 3.8m³ (4.97yd³)

Flat Floor Bucket 3.5m³ (4.57yd³)

Flat Floor Bucket 3.5m³ (4.57yd³)

Flat Floor Bucket 3.3m³ (4.25yd³)Performance Series

Flat Floor Bucket 3.4m³ (4.40yd³)Performance Series

Flat Floor Bucket 3.3m³ (4.25yd³)Performance Series

Flat Floor Bucket 3.4m³ (4.50yd³)Performance Series

Flat Floor Bucket 3.4m³ (4.50yd³)Performance Series

Flat Floor Bucket 3.6m³ (4.75yd³)Performance Series

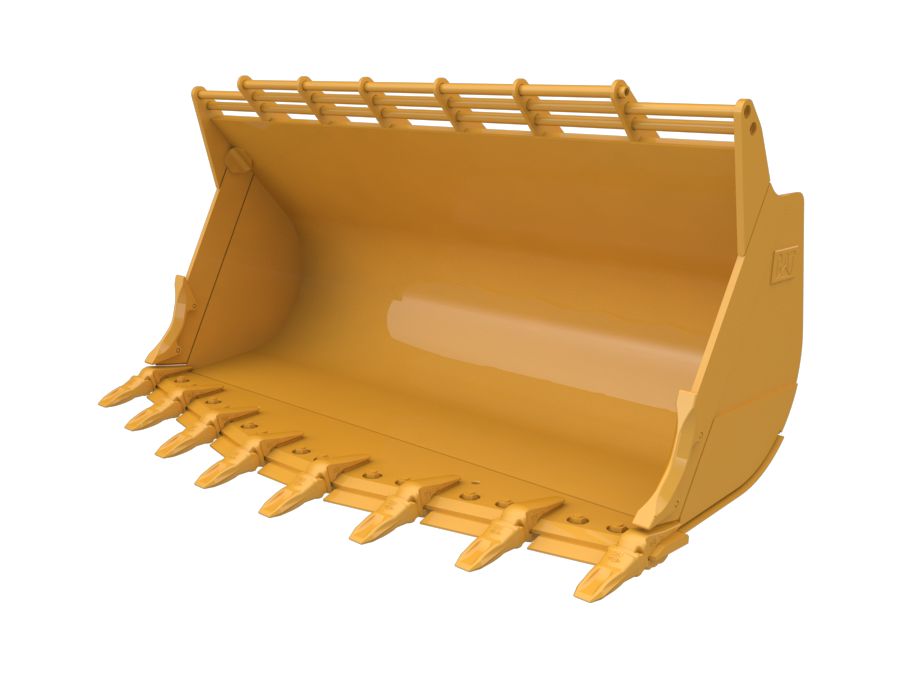

Flat Floor Bucket 5.2m³ (6.75yd³)Performance Series

Flat Floor Bucket 4.4m³ (5.75yd³)Performance Series

Flat Floor Bucket 5.7m³ (7.50yd³)

Flat Floor Bucket 9.2m³ (12.00yd³)

Flat Floor Bucket 9.2m³ (12.00yd³)

Flat Floor Bucket 9.9m³ (13.00yd³)

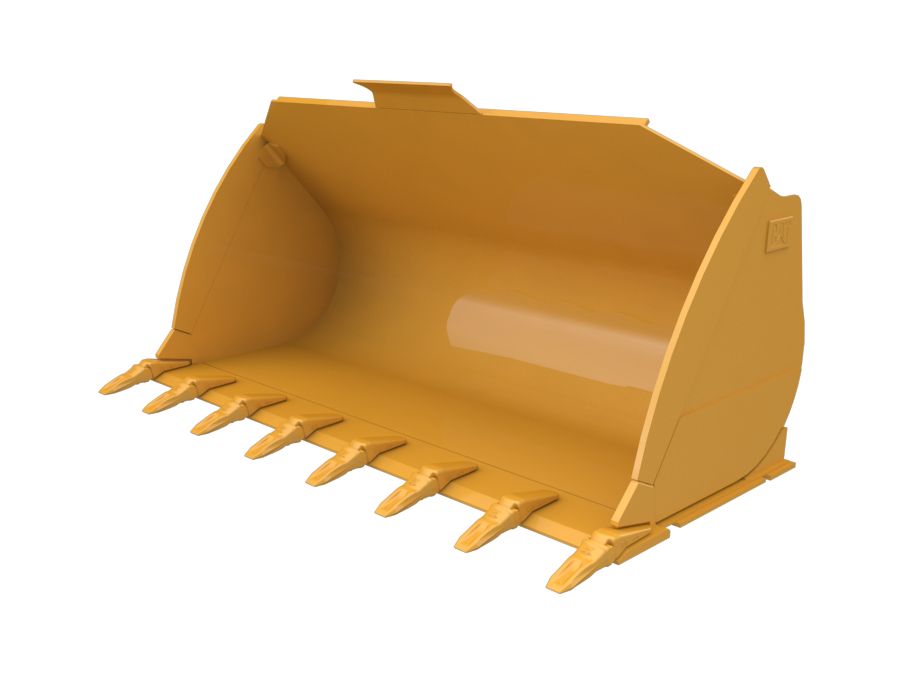

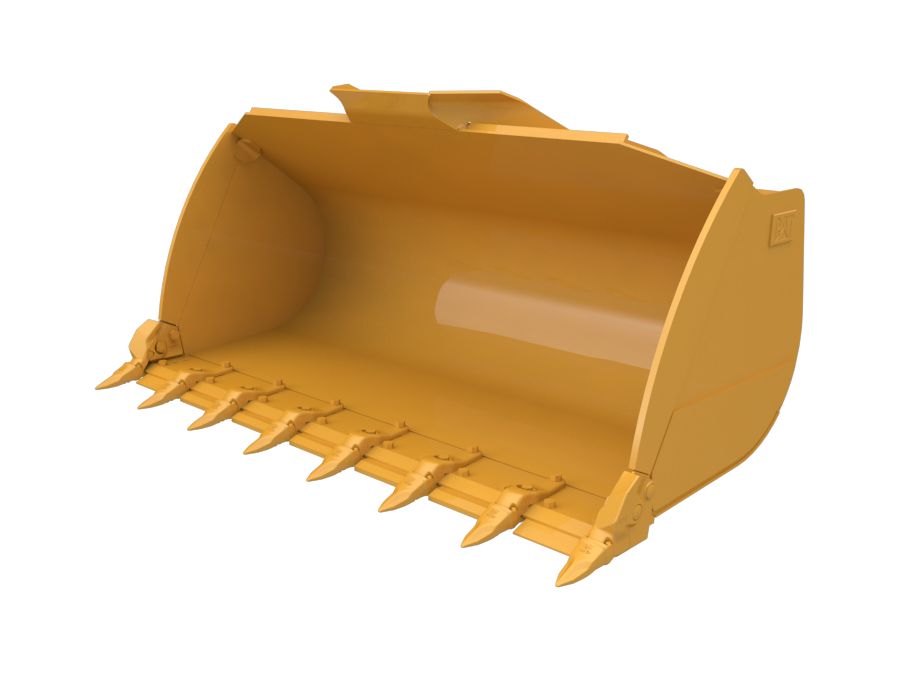

Rock Bucket 2.9m³ (3.75yd³)Performance Series

Rock Bucket 2.9m³ (3.75yd³)

Rock Bucket 3.1m³ (4.00yd³)Performance Series

Heavy Duty Rock Bucket 2.9m³ (3.75yd³)

Rock Bucket 2.9m³ (3.75yd³)

General Purpose Bucket 3.1m³ (4.00yd³)

General Purpose Bucket 3.1m³ (4.00yd³)

General Purpose Bucket 3.1m³ (4.00yd³)

General Purpose Bucket 3.1m³ (4.00yd³)

General Purpose Bucket 3.3m³ (4.25yd³)

General Purpose Bucket 3.3m³ (4.25yd³)

General Purpose Bucket 3.3m³ (4.30yd³)

General Purpose Bucket 3.5m³ (4.57yd³)

General Purpose Bucket 3.5m³ (4.57yd³)

General Purpose Bucket 3.3m³ (4.25yd³)Performance Series

General Purpose Bucket 3.1m³ (4.00yd³)Performance Series

General Purpose Bucket 3.4m³ (4.50yd³)Performance Series

General Purpose Bucket 3.1m³ (4.00yd³)Performance Series

General Purpose Bucket 3.3m³ (4.25yd³)Performance Series

General Purpose Bucket 3.3m³ (4.25yd³)Performance Series

General Purpose Bucket 3.4m³ (4.50yd³)Performance Series

General Purpose Bucket 3.6m³ (4.75yd³)Performance Series

General Purpose Bucket 3.3m³ (4.25yd³)Performance Series

General Purpose Bucket 3.1m³ (4.00yd³)Performance Series

General Purpose Bucket 3.1m³ (4.00yd³)Performance Series

General Purpose Bucket 3.4m³ (4.50yd³)Performance Series

General Purpose Bucket 3.6m³ (4.75yd³)Performance Series

General Purpose Bucket 3.1m³ (4.00yd³)Performance Series

General Purpose Bucket 3.2m³ (4.25yd³)Performance Series

General Purpose Bucket 3.4m³ (4.50yd³)Performance Series

General Purpose Bucket 3.3m³ (4.50yd³)Performance Series

General Purpose Bucket 3.4m³ (4.50yd³)Performance Series

General Purpose Bucket 3.6m³ (4.75yd³)Performance Series

General Purpose Bucket 3.6m³ (4.75yd³)Performance Series

General Purpose Bucket 3.8m³ (5.00yd³)Performance Series

General Purpose Bucket 4.0m³ (5.25yd³)Performance Series

General Purpose Bucket 4.2m³ (5.50yd³)Performance Series

950/962 Fusion Coupler

4585mm (180in) Mat'l handing Arm, Fusion™

4121mm (162in) Mat'l Handling Arm, Fusion™

4137 mm (163 in) Material Handling Arm, Fusion

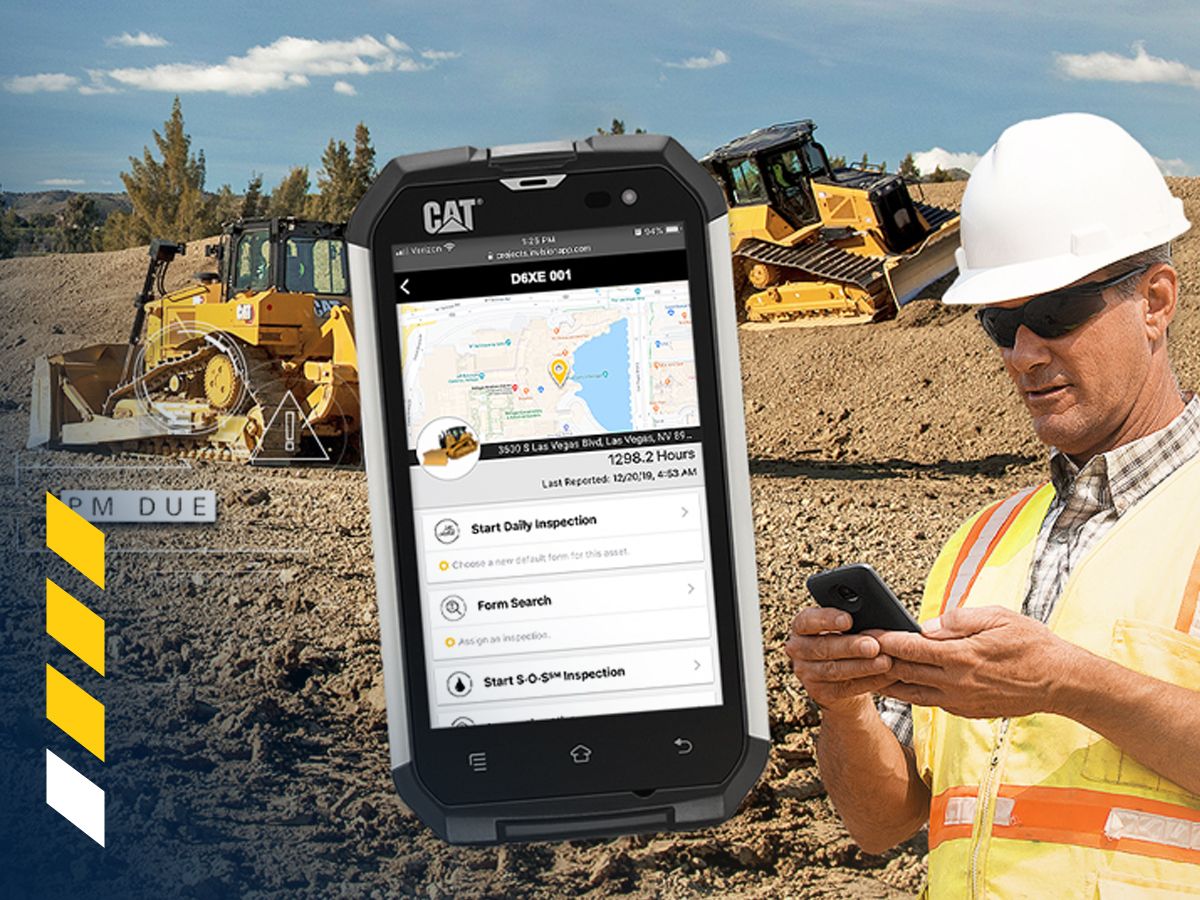

Cat® Detect with Smart Camera

Cat® Detect with Surround Cameras

Rear Object Detection for Wheel Loaders

Cat Product Link

Cat Inspect

VisionLink®